Long-run Steel Roofing and Cladding Profile

TRS Corrugate Steel Roofing and Wall Cladding System

TRS Corrugate

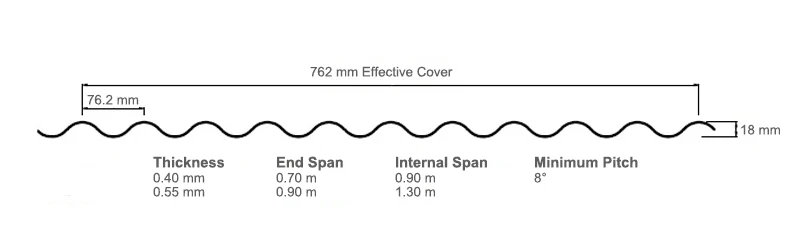

TRS Corrugate for roofing and cladding offers timeless elegance and unmatched adaptability with its traditional corrugated profile. It is for both residential and commercial applications. Its installation is suitable for timber and/or steel structures. Made from G550 grade steel with a minimum BMT of 0.40mm and a maximum BMT of 0.55mm, it provides enhanced resilience against damage.

General

Minimum Roof Pitch: 8°

Effective Cover: 762mm

Spans

End Span 0.40/0.55 BMT: 700 mm/900 mm

Internal Span 0.40/0.55 BMT: 900 mm/1300 mm

Roofing Fixings

Low/Medium Wind Zone

Timber: class 4 12 x 55mm with neo washer and embossed washer

Steeltite: 12 x 65mm with neo washer and embossed washer

High Wind Zone

Timber: class 4 12 x 55mm with neo washer and embossed washer, approved profile’s metal washer and EPDM washer.

Steeltite: 12 x 65mm with neo washer and embossed washer,

approved profile’s metal washer and EPDM washer.

Wall Cladding Fixings

Cladding fixing on 20mm, H 3.1 Treated Battens.

12 Gauge class 4 screws with neo washers, miss 2 pans, miss 3 pans every second on ends.

Note:

TRS Corrugate is long-run roofing and wall cladding systems. For use as roofing in extra high wind zones, the profile BMT should be 0.55mm, fixed with 12x65mm screws, and the purlin spacing should be 600mm center-to-center. The screw pattern for TRS Corrugate can be at every alternate crest.

For wall cladding in extra high wind zones, the BMT for both TRS Corrugate should also be 0.55mm, fixed with 12x50mm screws. TRS Corrugate can be fixed at alternate crests.

See below for TRS Corrugate product specifications and downloadable files:

Please note: all colours are available in 0.40mm. Colours marked with * are also available in 0.55mm.

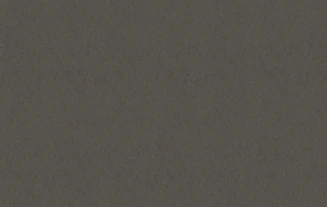

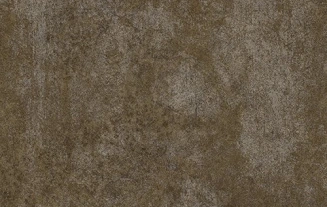

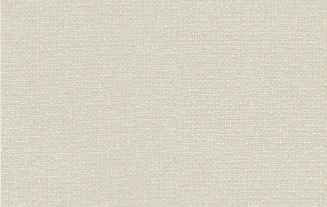

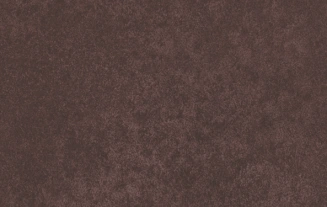

Colour & Finish Options – Lux

Please note:

All Lux finishes are available in 0.55mm base metal thickness, Grade G300, and are suitable for a wide range of architectural roofing, internal and external wall claddings, rainwater goods, and general applications.

While every effort has been made to match the displayed colours as closely as possible to the true colours, digital colour limitations may result in slight variations. For an exact colour match, please request a physical colour swatch from your local store.

Some profiles may have a limited colour range. For more information, consult with your local branch.

You can find the nearest local store by clicking here.